Connect With Our Team

As the world shifts toward cleaner and more sustainable energy sources, solar power continues to dominate the renewable energy conversation. However, many homeowners and even some professionals still get confused between solar cells and solar modules. Are they the same thing? Do they serve different purposes? And how do they impact the performance and cost of a solar energy system?

In this guide, we’ll break down the difference between solar cells and solar modules, why it matters, and what to consider when investing in solar panels for home use.

What Is a Solar Cell?

A solar cell, also known as a photovoltaic (PV) cell, is the fundamental building block of any solar energy system. It’s a small device made from semiconductor materials like silicon that convert sunlight directly into electricity through the photovoltaic effect.

When sunlight hits a solar cell, photons excite electrons in the material, generating a flow of electricity. This DC electricity is then used directly or converted into AC using an inverter.

Key Components of a Solar Cell

-

Material: Most solar cells are made from silicon wafers, though newer technologies use materials like thin-film cadmium telluride (CdTe), perovskites, or gallium arsenide, or other advanced semiconductors.

-

Size: Typically small, about 6 x 6 inches (156 mm) in commercial solar panels, though sizes vary depending on manufacturer and design.

-

Efficiency: The efficiency of a solar cell depends on its type monocrystalline, polycrystalline, or thin-film.

When sunlight (photons) hits the solar cell, it excites electrons within the semiconductor material, creating an electric current. Each cell generates only a small amount of electricity, usually around 0.5–0.6 volts.

That’s why a single solar cell isn’t enough to power appliances or homes, it needs to be combined with many other cells to generate significant electricity.

Types of Solar Cells

There are several types of solar cells, each with its own set of advantages and disadvantages:

1. Monocrystalline Solar Cells: Made from a single crystal of silicon, these cells are highly efficient and space-efficient. They are often found in monocrystalline solar panels and are ideal for residential installations with limited roof space.

-

Made from a single crystal of silicon.

-

High efficiency (18–23%).

-

Longer lifespan but more expensive.

2. Polycrystalline Solar Cells: Made from multiple silicon crystals, these are slightly less efficient but more affordable than monocrystalline variants.

-

Made from multiple silicon fragments melted together.

-

Moderate efficiency (15–18%).

-

More affordable but slightly less efficient.

3. Thin-Film Solar Cells: Lightweight and flexible, these are used in niche applications like foldable solar panels or solar-powered gadgets.

-

Made using thin semiconductor layers.

-

Flexible and lightweight.

-

Lower efficiency (10–13%) but ideal for portable or non-traditional applications.

Each type has unique efficiency, durability, and cost characteristics. Choosing the right type depends on your specific application and budget.

What Is a Solar Module?

While a solar cell is a small individual unit, a solar module is a larger, packaged product consisting of multiple solar cells connected in a specific layout. These cells are encapsulated within protective materials like tempered glass, a backsheet, and an aluminum frame to create a durable product suitable for outdoor use.

In everyday language, people often refer to a solar module as a solar panel, although technically, the panel refers to the assembly of one or more modules.

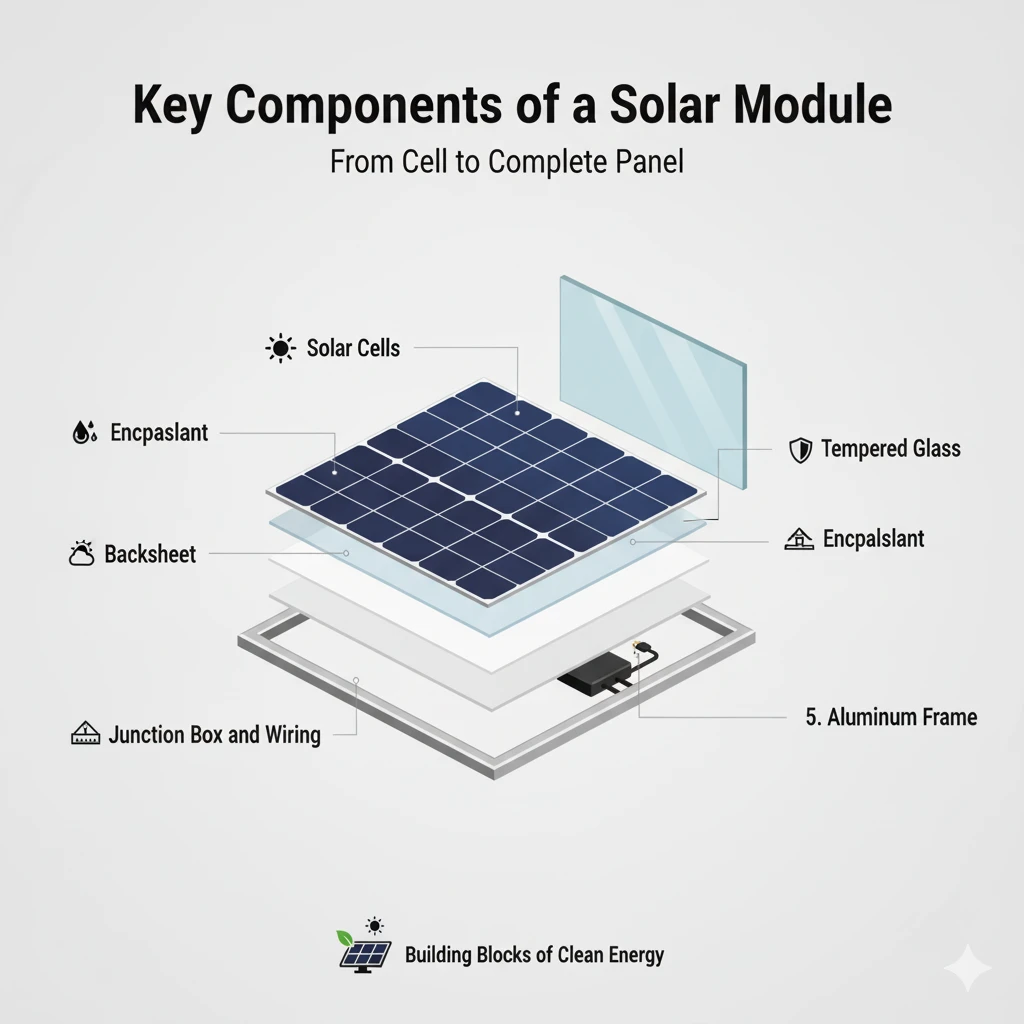

Key Components of a Solar Module

-

Solar Cells – The energy-generating elements.

-

Encapsulant – A transparent material that holds the cells in place and protects them.

-

Tempered Glass – Protects the cells from environmental damage.

-

Backsheet – Insulates and protects the back side.

-

Aluminum Frame – Provides structural support.

-

Junction Box and Wiring – Allows electrical connection.

All of these components work together to ensure the module can withstand wind, rain, snow, and long-term sun exposure.

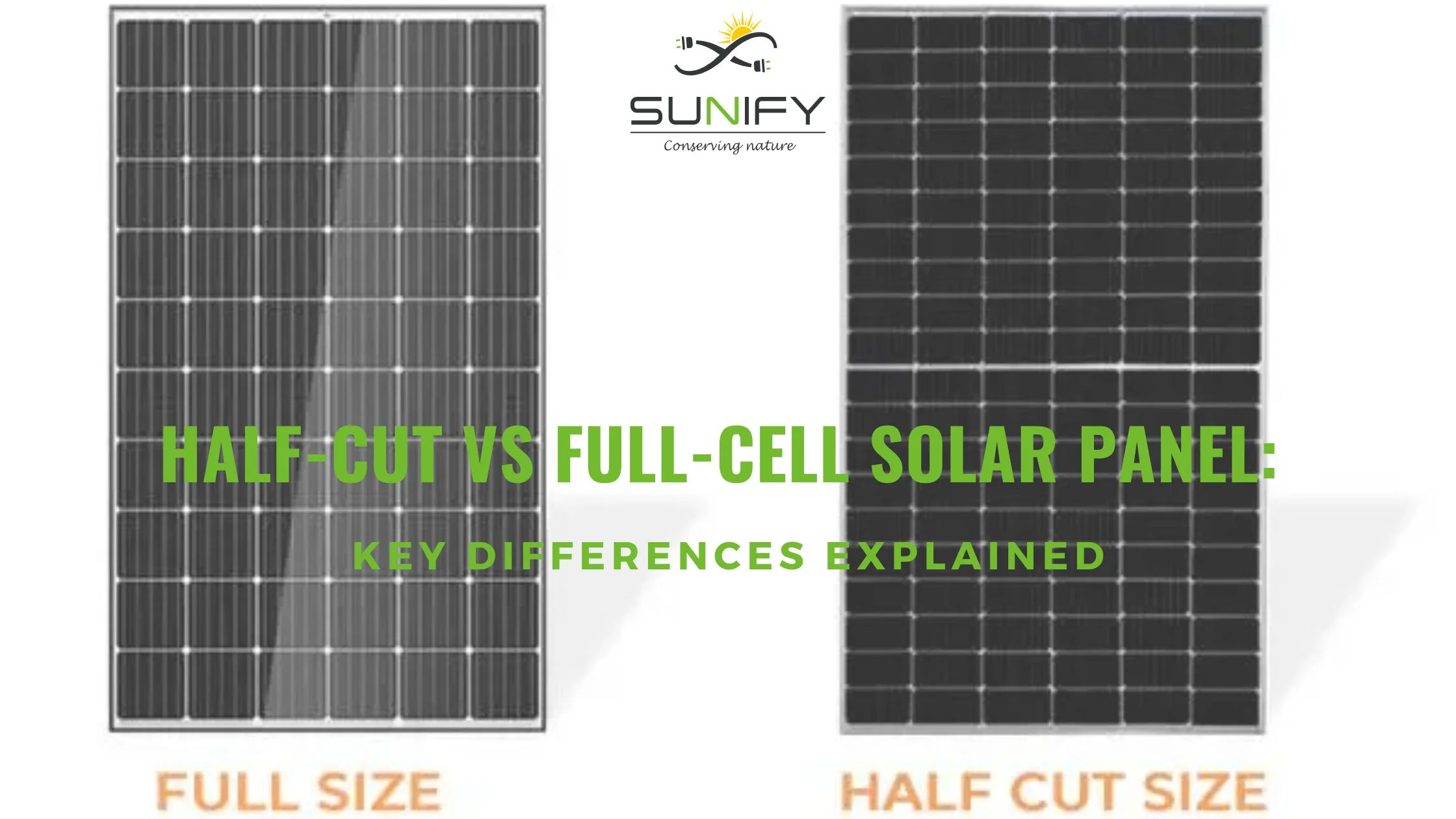

Types of Solar Modules

1. Monocrystalline Modules

Monocrystalline solar modules are made from single-crystal silicon, giving them a uniform structure and higher efficiency. Known for their premium quality and performance, these modules are ideal for areas with limited installation space.

-

Built from monocrystalline solar cells.

-

Higher efficiency (18–22%).

-

Sleek black appearance, ideal for limited roof space.

2. Polycrystalline Modules

Polycrystalline modules are manufactured from multiple silicon crystals melted together, making them cost-effective but slightly less efficient. As a more affordable choice, they are widely used in residential and commercial projects where space is not a major concern.

-

Built from polycrystalline cells.

-

Efficiency ranges from 15–18%.

-

Blue-tinted surface, more cost-effective.

3. Bifacial Modules

Bifacial solar modules are advanced panels that can capture sunlight from both their front and rear sides. Designed to maximize power output, they work especially well in environments with reflective surfaces like snow, sand, or white rooftops.

-

Can generate electricity from both the front and back surfaces.

-

Capture reflected sunlight for improved energy yield.

4. Thin-Film Modules

Thin-film solar modules are made using ultra-thin layers of semiconductor materials such as cadmium telluride or amorphous silicon. Popular for their lightweight and flexible design, these modules are best suited for unique applications beyond traditional rooftop installations.

-

Lightweight, flexible, and easier to integrate into buildings.

-

Typically lower efficiency but suitable for special applications.

Key Differences Between Solar Cells and Solar Modules

| Feature | Solar Cells | Solar Modules |

|---|---|---|

| Definition | Basic unit that converts sunlight to electricity | Collection of multiple solar cells in one panel |

| Size & Output | A few inches; ~0.5 volts per cell | 60–72 cells; ~30–40 volts per module |

| Applications | Toys, calculators, gadgets, research | Homes, businesses, industrial power systems |

| Durability | Fragile, easily damaged | Weatherproof, lasts 25+ years |

| Scalability | Not practical for large power needs | Scalable for residential and commercial projects |

How Solar Cells Become Solar Modules

The transformation from solar cells to solar modules involves several steps:

Cell Manufacturing

- Silicon ingots are sliced into thin wafers and treated to form PV cells.

Cell Interconnection

- Cells are wired together in series and parallel circuits to achieve desired voltage and current output.

Encapsulation

- The interconnected cells are sandwiched between protective layers (glass on top, polymer backsheet at the bottom).

Framing

- An aluminum frame is added for strength and mounting purposes.

Testing & Certification

- Modules undergo quality checks to ensure they meet performance and safety standards (IEC, UL, etc.).

By combining dozens of solar cells into one module, manufacturers create a product that can generate enough electricity to be useful in real-world energy systems.

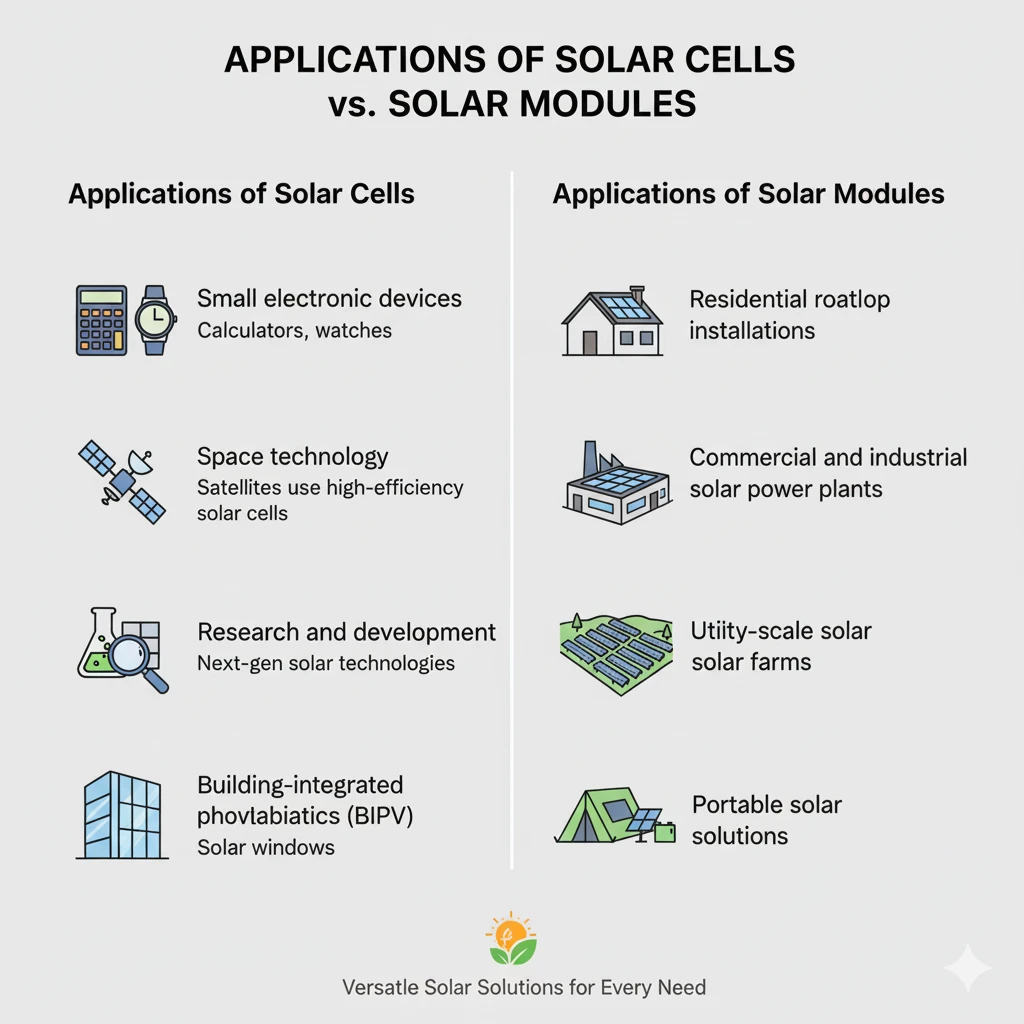

Applications of Solar Cells vs. Solar Modules

Applications of Solar Cells

-

Small electronic devices (calculators, watches).

-

Space technology (satellites use high-efficiency solar cells).

-

Research and development for next-gen solar technologies.

-

Building-integrated photovoltaics (BIPV), such as solar windows.

Applications of Solar Modules

-

Residential rooftop installations.

-

Commercial and industrial solar power plants.

-

Utility-scale solar farms.

-

Off-grid solar systems for rural areas.

-

Portable solar solutions (camping, RVs, marine).

Conclusion

The key takeaway is simple:

-

A solar cell is the individual unit that directly converts sunlight into electricity.

-

A solar module is a collection of many solar cells assembled into a usable panel that generates significant power.

Without solar cells, there would be no solar modules. But without solar modules, solar cells would be too small and fragile to power our homes, businesses, and cities.

Both are critical in the journey toward a renewable energy future. As technology improves, expect solar cells to become more efficient and solar modules to deliver higher power output at lower costs, making solar power more accessible worldwide

Recently Posted

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to solar@sunifysolar.in

|

************** +91 81414 55503 |

We will love to hear from you!