Connect With Our Team

The rise of smart factories has transformed manufacturing with automation, data intelligence, and connected machines. But as production becomes more advanced, energy consumption goes up too. Many industries now face increasing electricity bills, unstable grid supply, and pressure to adopt cleaner technologies.

This is where solar power has become a game-changer. From lowering operating costs to improving efficiency, solar energy fits perfectly into the framework of smart manufacturing technologies. With the help of intelligent monitoring systems, modern factories can maximize solar output and minimize energy waste creating a reliable, cost-efficient, and sustainable manufacturing environment.

This blog explores how solar power helps smart factories significantly reduce energy expenses while supporting long-term sustainability goals.

Why Are Energy Costs Increasing for Modern Factories?

Smart factories rely heavily on automated equipment, robotics, IoT sensors, and data-driven workflows. These advanced systems operate around the clock, and their energy needs are far higher than traditional machinery.

Peak-hour tariff hikes, rising grid dependence, and fluctuating power quality also contribute to increasing costs. Many manufacturing units now run diesel generators as backup, which further adds to operational expenses.

Switching to solar power for business and industrial use offers a stable, predictable, and cost-effective solution to this growing problem.

What Makes Solar Power Ideal for Smart Factories?

1. Solar energy fits seamlessly with smart manufacturing technologies

Modern factories use energy monitoring tools, IoT-based meters, and intelligent automation systems. A solar panel system can integrate into these tools, allowing factories to track real-time solar production, energy savings, and load distribution.

2. Reliable and long-lasting power source

Industrial solar panels have a lifespan of 20–25 years with minimal maintenance. Combined with a solar inverter, factories receive clean and stable electricity suitable for sensitive machinery.

3. Flexible installation options

Factories can choose:

-

Rooftop solar panel installation

-

Ground-mounted industrial solar system

-

Solar + battery storage solutions

These options make solar power adaptable to different factory layouts and energy needs.

How Solar Power Cuts Energy Costs in Smart Manufacturing

1. Reduces Dependence on Expensive Grid Electricity

A large portion of a factory’s energy requirement can be met through solar panels during the daytime. This significantly reduces monthly bills and exposure to peak tariffs.

Factories using solar power for commercial use often report energy bill reductions of 30–60%, depending on their capacity and load pattern.

2. Maximizes Savings with Net Metering

With net metering, factories can export excess solar energy back to the grid and receive bill credits. This helps:

-

Offset electricity costs during non-operating hours

-

Stabilize monthly billing

-

Improve overall return on investment

For factories with large rooftops, net metering becomes one of the biggest cost-saving opportunities.

3. Solar + Storage Minimizes Downtime and Backup Costs

Energy interruptions can halt production lines, damage inventory, or cause delays. Smart factories depend on uninterrupted power.

A combination of solar power and a battery backup can:

-

Reduce diesel generator usage

-

Maintain stable voltage

-

Prevent unplanned downtime

-

Support critical loads with clean energy

In industries where precision and consistency matter, reliability is as important as cost savings.

4. Lower Operational Expenses Over the Long Term

While solar panel cost may seem significant upfront, the long-term savings outweigh the investment. Most factories recover their costs within 3–5 years due to major reductions in electricity bills.

After that, solar energy becomes almost free for the remaining lifespan of the system.

How Smart Energy Management Maximizes Solar Savings

Smart factories rely on digital tools to manage energy efficiently. When paired with sunpower solar systems or other high-efficiency modules, these tools amplify cost savings.

1. Real-time load balancing

AI-driven dashboards distribute solar energy to high-priority equipment first, ensuring maximum utilization.

2. Automatic peak-load shifting

Factories can shift high-energy processes to sunlight hours when solar output is maximum.

3. Predictive maintenance

IoT sensors detect dust buildup, shading issues, or inverter inefficiencies before they impact production.

4. Smart grid synchronization

The system automatically switches between solar, grid, and battery based on cost and availability.

What Are the Financial Benefits of Solar Power for Factories?

1. Short Payback Period

Industrial users benefit from high daytime consumption, which matches peak solar generation. This speeds up payback and boosts ROI.

2. Lower Per-Unit Production Cost

Since energy is one of the biggest contributors to per-unit production cost, reducing bills directly increases profitability.

3. Reduced Overhead Costs

With commercial solar installation, factories spend less on generator fuel, grid electricity, and maintenance.

4. Tax Benefits

Government incentives, accelerated depreciation, and subsidies further reduce the effective price of a solar investment.

Return on Investment (ROI) & Payback Period

Factories frequently evaluate solar panel cost against long-term savings. While upfront investment may seem significant, the financial return is equally powerful.

-

Average payback period: 3 to 5 years

-

Average system life: 25+ years

-

Long-term electricity cost reduction: 60% to 80%

Once the system is paid off, businesses enjoy virtually free electricity for decades.

Real-World Examples: How Smart Factories Benefit from Solar Energy

Automotive industry

Robotic welding stations and assembly lines consume massive amounts of electricity. By adopting solar power for factories, automotive manufacturers often reduce grid usage by up to 40–50%.

FMCG factories

High energy use for packaging, refrigeration, and conveyors makes solar ideal for daytime loads.

Textile units

These units run high-capacity motors, heating machines, and looms making them perfect candidates for solar adoption.

Electronics manufacturing

Precision equipment benefits from clean, stable energy supplied through a good solar panel system and inverter combination.

Key Factors to Consider Before Installing Solar in Your Factory

1. Assessing Current and Future Energy Needs

Factories should evaluate their energy consumption patterns, peak hours, and load requirements before deciding on the right system size.

2. Choosing Between Rooftop and Ground-Mounted Installations

Rooftop installations are common, but factories with large open spaces may prefer ground-mounted setups for higher capacity.

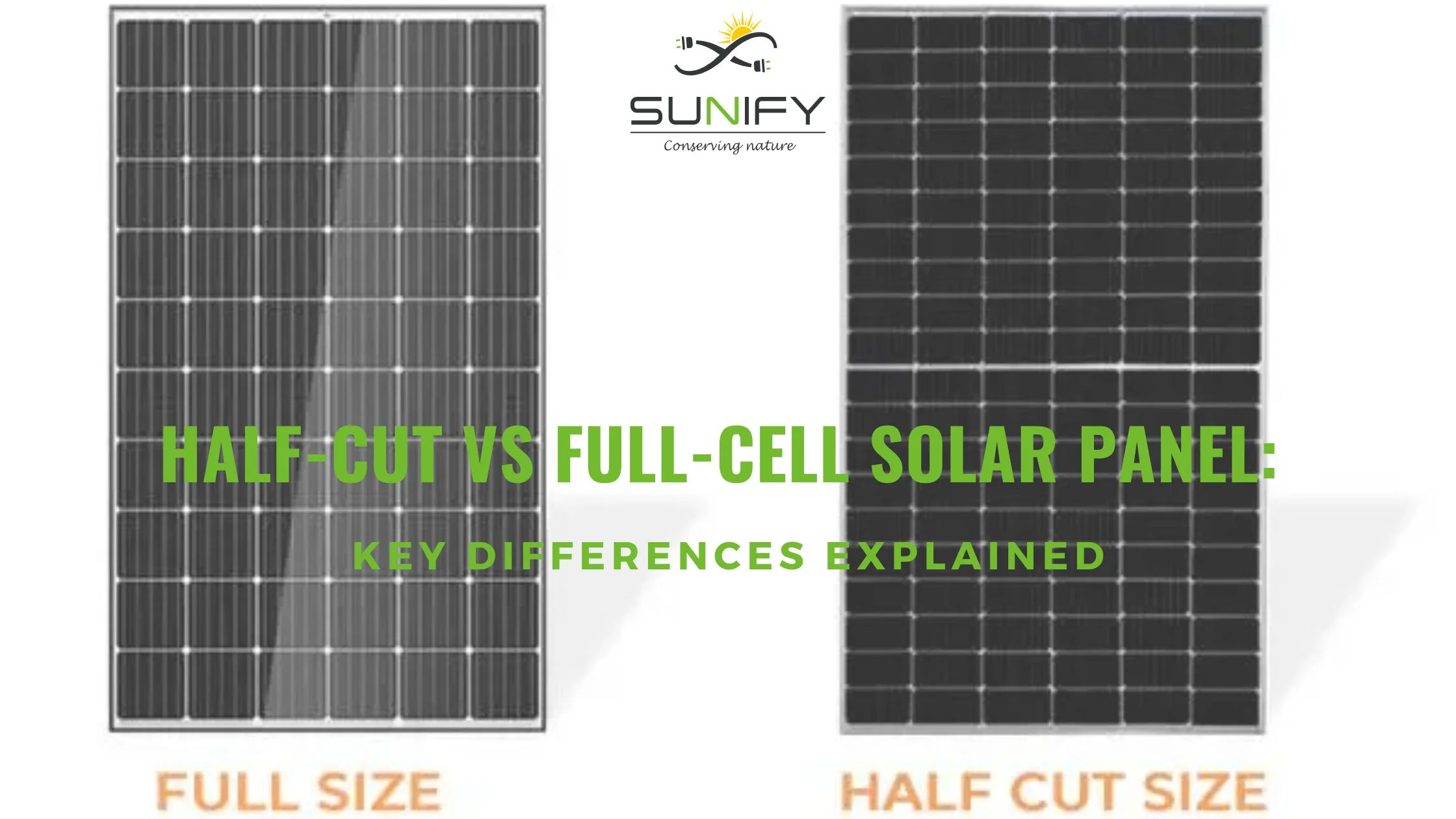

3. Choosing the Right Solar Technology

High-efficiency options like sunpower solar modules or bifacial panels ensure better output and faster payback.

4. Selecting the Right Installation Partner

Experienced commercial solar installation companies provide:

-

Correct system sizing

-

High-quality installation

-

Access to monitoring software

-

Efficient after-sales support

5. Ensuring System Scalability

Factories should plan for future expansions by choosing modular solar designs.

Government Incentives & Policies for Factory Solar Installation

Governments worldwide are encouraging industries to move toward renewable energy by offering major incentives:

-

Capital subsidies

-

Accelerated depreciation benefits

-

Net metering policies

-

Green certification advantages

-

Carbon credit benefits

These incentives significantly reduce solar panel cost and improve return on investment for manufacturers.

Future of Solar-Powered Smart Factories

AI-Based Energy Intelligence

AI systems will automatically distribute solar power, optimize load patterns, and predict energy needs.

Microgrids for Industrial Clusters

Manufacturing parks can share solar resources, lowering energy costs across multiple factories.

Growth of Solar Storage Systems

As battery prices drop, solar + storage will become the norm for industrial facilities.

EV Integration

Factories operating electric forklifts, delivery vans, or internal transport vehicles can charge them using solar energy.

Sunify Solar – Smart Solar Solutions for Factories & Commercial Projects

Sunify Solar specializes in delivering high-performance solar panel systems customized for smart factories and industrial infrastructure. Their expertise in designing industrial solar systems ensures maximum energy output with optimized space utilization.

With complete project execution, professional commercial solar installation, and long-term maintenance support, Sunify Solar empowers factories to transition seamlessly to reliable and affordable solar power for business operations.

Conclusion

Solar power is no longer just a sustainability trend it is a practical, cost-saving solution for modern smart factories. With the help of intelligent systems, IoT tools, and smart manufacturing technologies, factories can optimize solar usage, reduce energy bills, and improve production efficiency.

Adopting solar power for business not only lowers operating costs but also strengthens long-term energy independence. From automotive plants to FMCG and textile units, every manufacturing sector can benefit from a solar power commercial use strategy.

As electricity prices rise and automation increases, the factories that invest in solar today will lead the future of sustainable and efficient manufacturing.

FAQs

1. How much can solar power reduce factory electricity bills?

On average, factories reduce electricity costs by 30% to 70% depending on plant size, operational hours, and system capacity.

2. Is solar energy reliable for 24/7 factory operations?

Yes. With hybrid systems and battery storage, solar energy ensures uninterrupted production even during grid failures.

3. What is the lifespan of industrial solar panels?

Most industrial solar panels operate efficiently for 25 to 30 years with minimal maintenance.

4. Can smart factories run completely on solar power?

Yes. Many green factories operate on 100% solar power for factories using advanced battery storage and hybrid systems.

5. Is solar panel installation expensive for factories?

While solar panel cost depends on capacity, subsidies and long-term bill savings make it highly profitable within a few years.

Recently Posted

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to solar@sunifysolar.in

|

************** +91 81414 55503 |

We will love to hear from you!